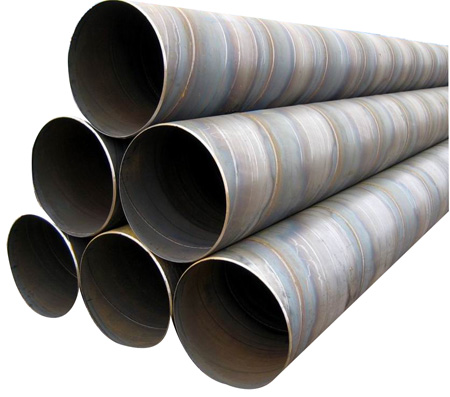

Disadvantages Of Welding Steel Pipe

Welding steel pipe is best sale steel products online. The thicker the thickness is, the greater the investment of unit and dissolution is. And it is much less economical and practical. However, the thinner wall thickness is, the less input-output will be. The production of welding pipe decides the advantages and disadvantages.Welding Steel Pipe

Common Defects and Disadvantages of Welding Steel Pipe

1. Layered steel

Layered steel pipe is referred to the wall thickness is divided into two layer on the cross section of steel tube. The layer is exposed to the surface longitudinal cracks of pipe. Some local concave-convex surface is rendered both inside and outside the pipe. While the welding line inside and outside of layered precipitously convex or concave will become warp skin.

2. The glue scar is to the surface inside and outside of steel pipe is adhered to massive scabbing.

3. Steel tube holes exist in local throughout GuanBi holes

4. Welding line is an inevitable partial cracks for welding steel pipe.

5. Local lap welding.

6. Welding groove.

7. Flat welding.

9. Pipe fitting dislocation.